Inject speed in your label imposition

With increasing label SKUs of shorter run lengths, are you spending more time, effort and money in creating impositions?

Are you maximizing returns from your high value investments by ganging/nesting multiple SKUs together?

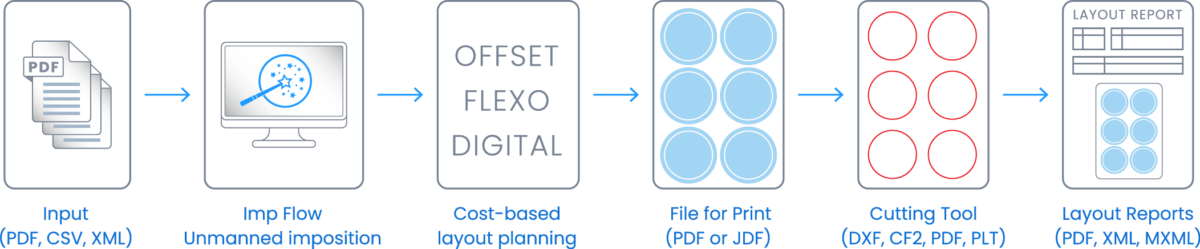

Software intelligence completely automates ganging and step and repeat of labels on offset, flexo and digital web presses. No need to maintain separate label imposition software for different equipments.

Use automatically generated layouts that minimize material wastage and maximize productivity, to raise accurate quotes and win more orders.

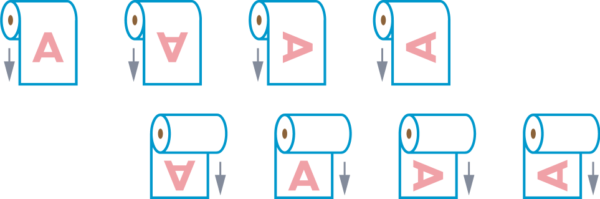

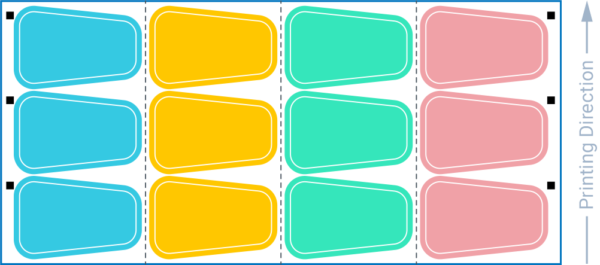

Just choose the preferred reel unwinding direction per job and let the software automatically orient the labels correctly on the layout.

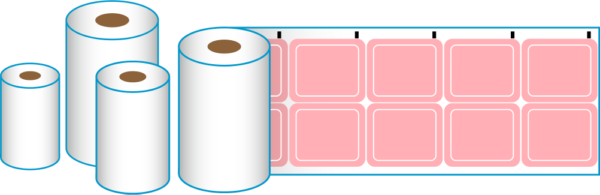

Let the label imposition software automatically select the best reel width, number of ups and lanes as per order quantity.

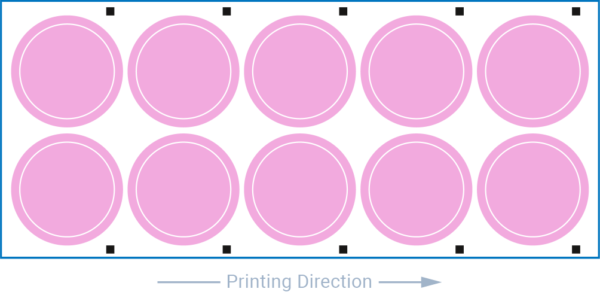

Exercise full control and automation on how eye-marks for registration and finishing are placed on the layout.

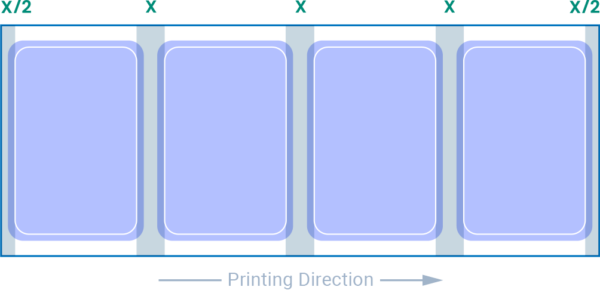

Labels are placed with uniform gap between each row on the layout for continuous reel printing and finishing.

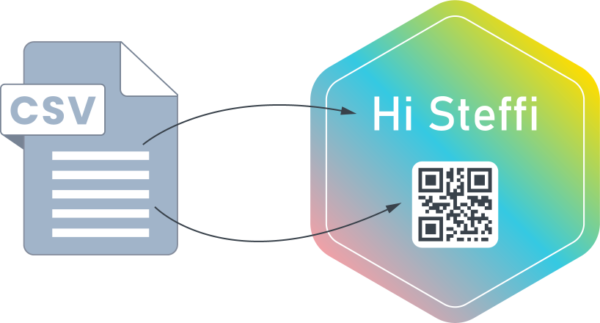

Add personalized QR codes, bar codes & text from CSV or XML file to each SKU.

The best label imposition software to control number of lanes supported by your finishing device.

Gang different versions of same label order of different quantities with complete control on number of lanes.

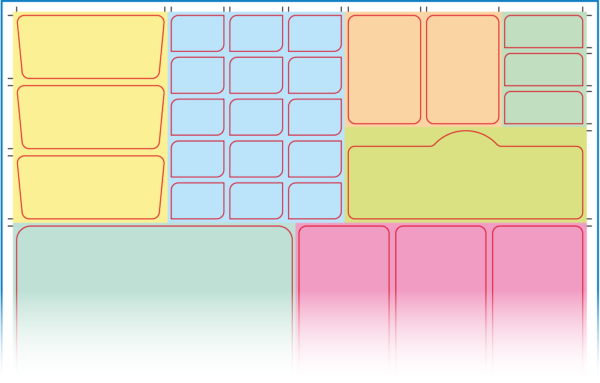

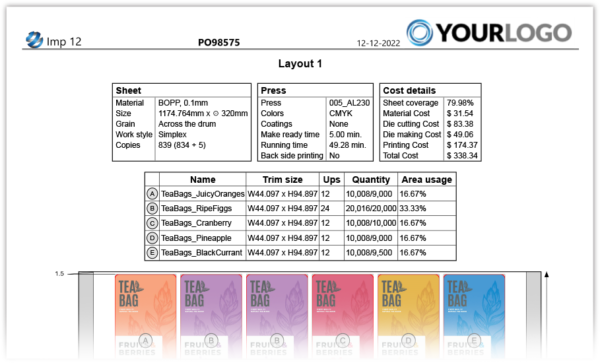

Create combo-layouts of different labels to optimize material, printing and finishing setups, while maintaining equal gap between each label!

Gang different labels on offset presses. Special algorithm for offset printing takes plates, make-ready time/waste, and running waste into account to calculate best layout.

Option to define UPC codes in job input for each SKU allows user to control planning – to place same UPC code SKUs on different layouts or together – Automatically!

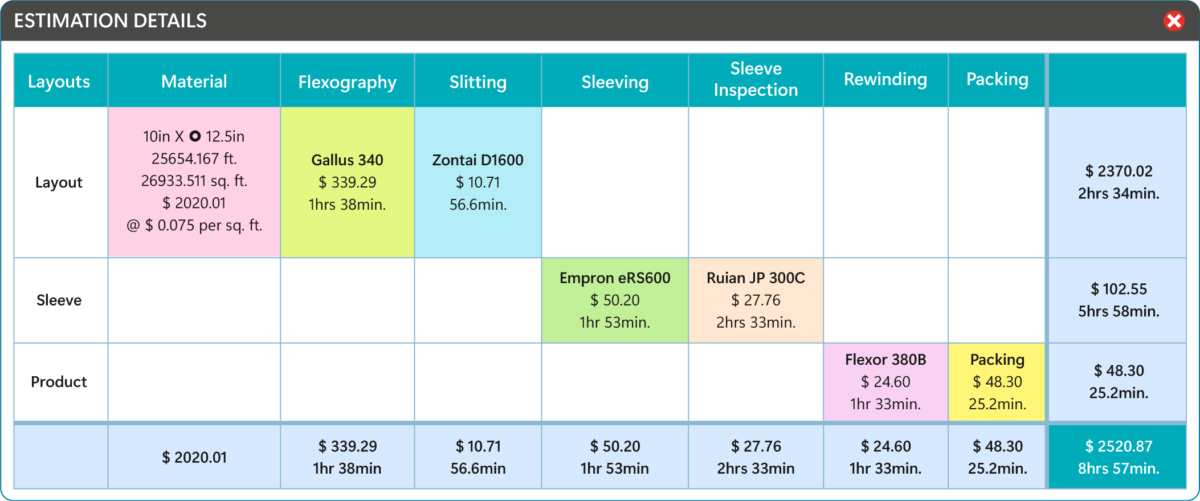

Cost efficient job routing is computed before generating the quote, which means a complete job-card can be generated at the time of estimation.

Imp Flow is a hot-folder based software application built on top of Imp software. It leverages the inherent intelligence of the Imp software to provide unparalleled automation in layout planning and imposition.

Export imposed PDF/JDFs for print. Die-layouts in CF2, DXF, PDF, PLT or ZCC (Zund) format.

Imp software can export comprehensive data of layouts, costs, operations and materials used in PDF, XML, CSV or MXML formats.

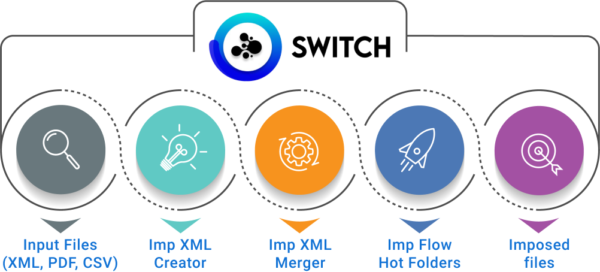

A comprehensive SDK (software development kit : API) on .Net6 is available for integration with MIS/ERP or custom developed solutions.

Imp Flow application seamlessly integrates into your SWITCH flow to give end-to-end automation. The first time a file is touched is when it is sent on printing device.